One of the biggest headaches in agricultural spraying is getting your crop protection products safely loaded, mixed and transported to the sprayer in as little time as possible, all while minimizing product contact. The Handler accomplishes this.

The Handler is a line of chemical handling systems that enables quick, easy and safe mixing and loading of agricultural chemicals into sprayers, airplanes and hauling tank systems. Originally developed by a Canadian farmer who was tired of having to climb onto his sprayer to dump gallon jugs of chemical, only to then have to fight with rinsing them, The Handler has evolved into a total crop protection management system.

Available in 20 different models, and loaded with innovative features, The Handler has been proven on tens of thousands of farms across the world to reduce the time it takes to properly mix and load a sprayer. The key to a successful spraying operation is to spend less time loading and more time spraying, all without sacrificing safety. The Handler combines safety, speed and effectiveness into a unit which will become the lifeblood of any spraying operation.

Each model comes with a wide variety of features designed to ease the loading process:

- Available in FOUR (4) convenient sizes – 15, 42, 70 & 230 US gallons

- Capable of handling liquid, dry and bulk product

- Built-in bulk handling capability

- Fills your sprayer fast, safely and effectively

- Patented knife system to maximize mixing speed and minimize waste

- Ensures safe disposal of chemicals and minimizes exposure.

- Fresh water rinse line for equipment cleanup and line rinsing

- Weatherproof and UV resistant black hose throughout

- Dedicated, venturi powered bulk suction line

- Exclusive double venturi for easy emptying of bulk containers

- 3” seamless Handler bypass offers the highest volume bypass flow yet!

The Handler is a great investment for your spraying operation, you’ll wonder why you didn’t buy one before!

The Handler became the top selling specialty loading system in North America because of its ability to cut, empty and rinse a container in seconds. As spraying has changed, so has The Handler. In addition to The Handler knife, the system also mixes powders and dry products easily and quickly, draws from bulk containers using the Handler venturi on select models, and utilizes cone-bottom tanks to easily accommodate batch mixtures and bulk chemical metering.

THE HANDLER COMES COMPLETE WITH:

- 2 or 3 inch camlocks for easy hook -up

- A proprietary, high-performance dual inlet venturi fitting, to empty your Handler in seconds using only the water flow from virtually any transfer pump (Handler I, II & III)

- Bulk adapter connections to draw chemical directly from bulk containers or totes without the need for a separate, slow chemical pump (Handler II, III and IV Models).

- A high-visibility, calibrated, cone-bottom tank that works on any terrain

- Optional frames that accommodate any 2 or 3 inch transfer pump (Handler II, III & IV)

- Optional recirculation packages to allow for batch mixing (Handler II, III & IV)

THE SECRET OF THE HANDLER KNIFE:

The Handler uses the original knife system to cut plastic chemical containers, empty their contents for mixing, and fully rinse the container for safe disposal. This is all done in less than 30 seconds while filling your sprayer! There is no waste or residue chemical left in the container once rinsed. Working in conjunction with the custom-designed venturi, The Handler will save you time and money, as well as decrease your risk of exposure to potentially harmful chemicals.

The Handler uses the original knife system to cut plastic chemical containers, empty their contents for mixing, and fully rinse the container for safe disposal. This is all done in less than 30 seconds while filling your sprayer! There is no waste or residue chemical left in the container once rinsed. Working in conjunction with the custom-designed venturi, The Handler will save you time and money, as well as decrease your risk of exposure to potentially harmful chemicals.

FEATURES AND BENEFITS

Increased speed and the reduction of the bottlenecks normally associated with loading a sprayer are the keys to spending less time loading the sprayer and more time using it. The Handler EXCLUSIVE double venturi allows for easy and seamless suction between the Handler tank and an outside bulk container.

Draw from bulk containers using your Handler II, III, and IV. By adding a 1” or 2” Banjo magnetic flow meter, 1” GPI flow meter, or Dura Meter for optional metering, you use the Handler venturi to directly induct product into the fill line. This non-mechanical process eliminates the need for slow chemical pumps and simply won’t break down.

Draw from bulk containers using your Handler II, III, and IV. By adding a 1” or 2” Banjo magnetic flow meter, 1” GPI flow meter, or Dura Meter for optional metering, you use the Handler venturi to directly induct product into the fill line. This non-mechanical process eliminates the need for slow chemical pumps and simply won’t break down.

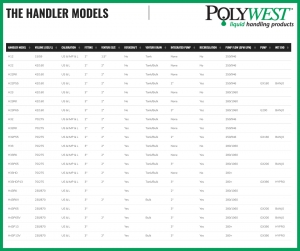

HANDLER MODELS

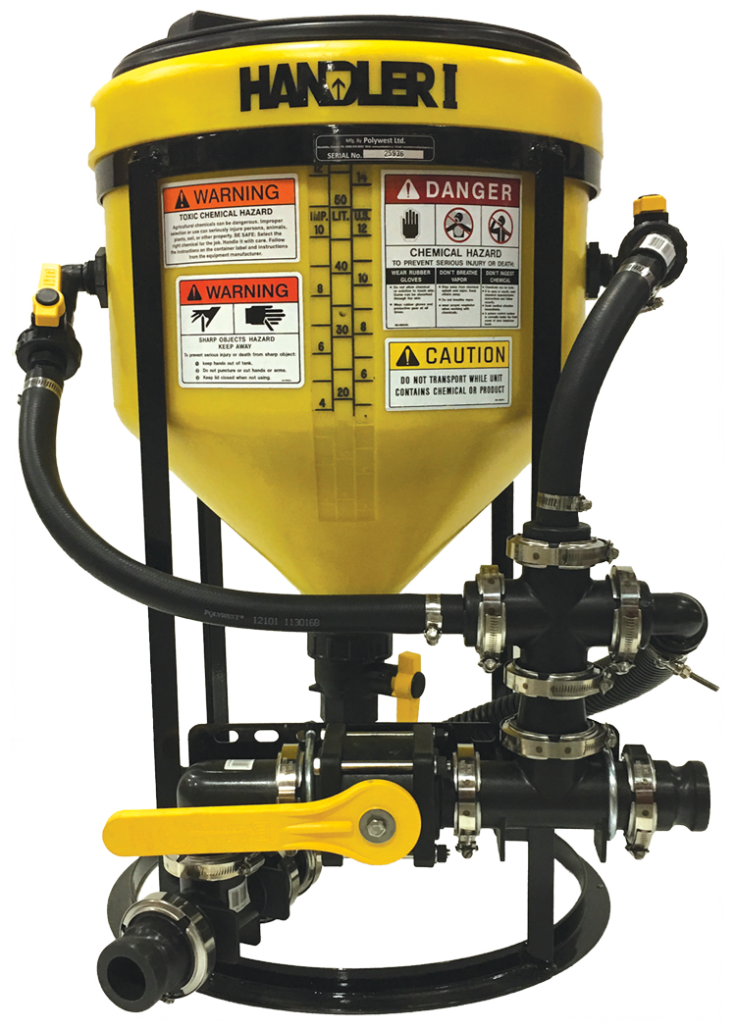

H12

The H12 is the most compact Handler and is designed for direct induction of chemical into sprayers. This is the leanest model that will pierce, empty, and clean 10L and 20L jugs without slowing down your sprayer filling. Ideal for one man operations, those with limited space, and anyone looking to improve the jug-handling tanks that come with most new sprayers. The Handler I is a free standing unit and is a popular factory installed option with some of the top sprayers on the market today.

The Handler I also features a special venturi designed for sprayers with capacities of 500 gallons or less. Features and benefits include:

- Compact space saver.

- Comes with the original Handler knife.

- Capable of piercing, emptying and rinsing 10L/20L containers easily.

- Simple four-valve operation.

QUICK SPECIFICATIONS

- 15 US GAL/59 L

- 2” CAMLOCK CONNECTIONS

- 16” THREADED LID

- 1.5” VENTURI

H22 and H2P55

The H22P55 is all of the functionality you need for sprayer filling in a compact and cost-effective platform. The integrated transfer pump performs sprayer filling along with all of your liquid and dry handling needs; closed loop recirculation and agitation, bulk chemical induction, 10L/20L container emptying and rinsing, direct chemical induction to sprayer. The field tested valve arrangement allows you to use it whichever way suits your application; a venturi based system that keeps the water pump free of chemical at all times, or a closed loop recirculation system for aggressive agitation and even faster chemical handling.

The H22P55 comes standard with Handler’s proprietary dual-inlet venturi. This allows the venturi to draw from the Handler tank or from a bulk chemical container without any extra plumbing or hoses. Features and benefits include:

- Full 10L/20L container emptying and rinsing capabilities.

- Comes with The Handler knife.

- Closed loop recirculation.

- Venturi with Handler and bulk draw capabilities.

- Tank can be emptied via the venturi or via direct pump draw.

Note: The H22 model is identical but excludes the pump.

H23

The H23 is the most compact model that still offers all the flow and functionality of the larger models. Suitable for everything from dry flowables to 10L and 20L containers to bulk containers, this is the most compact 3” inductor system on the market. Water is simply pumped to the inlet of the H23, which provides the flow to agitate and fill the tank, empty and rinse containers, power the dual-inlet venturi, rinse the tank, and of course transfer water to your sprayer tank.

The Handler’s exclusive dual-inlet venturi comes plumbed to draw from your choice of the Handler tank or your bulk containers directly into your sprayer fill line. The full 3” bypass line on the H23 is designed to handle the rigors of any pump with capacities of up to 280 GPM (1060 LPM) without any concern for pressure. Banjo’s exclusive sweep elbows are used to eliminate as much line turbulence as possible. Features include:

- Full 10L/20L container emptying and rinsing capabilities.

- Comes with the original Handler knife.

- Dual inlet venturi with Handler and bulk draw capabilities.

- Durable 3” bypass for flows up to 280 GPM.

QUICK SPECIFICATIONS

- 42 US GAL/160L

- 3” CAMLOCK CONNECTIONS

- 16” HINGED AND LOCKABLE LID

- 2” DUAL INLET VENTURI

H23P65

The H23P65 is the industry’s smallest complete inductor system to utilize a full 3″ plumbing system. Utilizing sweep elbows to reduce corner turbulence, the H23P65 bypasses water to your sprayer with almost no drop in pump output.

The Banjo 3″ transfer pump (the proven 300PO) is powered by a Honda GX200 engine. Honda has tested this Handler configuration and as a result your Handler’s Honda engine is covered by Honda Warranty at any authorized service centre in the world. For periodic users of dry flowables, solubles, or AMS the Handler H23P65 is an ideal choice. Features include:

- Full 10L/20L container emptying and rinsing capabilities.

- Comes with the original Handler knife.

- Dual inlet venturi with Handler and bulk draw capabilities.

- High volume 3” bypass to maximize pump flow and reduce tank fill time.

- Closed loop recirculation and agitation.

H32P55

After 25 years, the H32P55 remains one of the best-selling models in the entire Handler lineup. A larger 70 US gallon tank allows for handling higher volumes of dry flowables and powders which can be easily mixed into solution with the integrated pump and closed loop recirculation. Full functionality includes: Handler tank filling and agitation, closed loop recirculation, dual inlet venturi draw from your choice of Handler tank or bulk containers, 10L & 20L container emptying and rinsing, tank rinsing, a wash line, and of course water transfer to the sprayer tank.

All the functionality with a larger tank, combined with cost effective 2” plumbing and pump, make the H32P55 a steady favorite on the farm. Features include:

- Full 10L/20L container emptying and rinsing capabilities.

- Dual inlet venturi and bulk draw capabilities.

- Integrated transfer pump.

- Comes with the original Handler knife.

- Closed loop recirculation and agitation.

- Tank emptying by venturi or direct pump draw.

Note: The H32 model is identical, but excludes the pump.

QUICK SPECIFICATIONS

- 70 US GAL/275L

- 2” CAMLOCK CONNECTIONS

- 16” HINGED AND LOCKABLE LID

- 2” DUAL INLET VENTURI

- 2” BANJO PUMP/GX200 HONDA ENGINE (exculded on H32 model)

- ROTACRAFT TANK RINSING NOZZLE

H33

The H33 is the super-sized version of the popular H23. With its larger tank it is perfect for handling everything from dry flowables, to 10L and 20L containers, to bulk containers. Water is simply pumped to the inlet of the H33 which provides the flow to agitate and fill the tank, empty and rinse containers, power the dual inlet venturi, rinse the tank, and of course transfer water to your sprayer tank. The Handler exclusive dual inlet venturi comes plumbed to draw from your choice of the Handler tank or your bulk containers, directly into your sprayer fill line.

The full 3” bypass line on the H33 is designed to handle the rigors of any pump with capacities of up to 280 GPM (1060 LPM) without concern for pressure. Banjo’s sweep elbows are used to eliminate as much line turbulence as possible. To ensure this larger tank size can be thoroughly cleaned, all H3 models incorporate the Rotacraft tank cleaning nozzle. Features include:

- Dual inlet venturi and bulk draw capabilities.

- Full 10L/20L container emptying and rinsing capabilities.

- Durable 3” bypass for flows up to 280 GPM (1060 LPM).

- Comes with the original Handler knife.

QUICK SPECIFICATIONS

- 70 US GA70 US GAL/275L

- 3” CAMLOCK CONNECTIONS

- 16” HINGED AND LOCKABLE LID

- 2” DUAL INLET VENTURI

- ROTACRAFT TANK RINSING NOZZLE

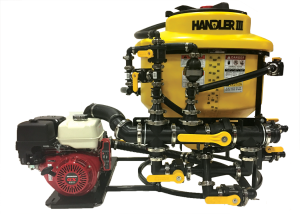

H33P65

The H33P65 has been the most popular on-farm model for many years. The large 70 US gallon tank combined with the steep cone tank, agitation nozzle, and dual inlet venturi make this the most versatile of all Handlers. With capacity to agitate larger volumes of dry products the H33P65 is commonly found in areas where high volumes of AMS are used. Due to the larger tank size, a Rotacraft tank rinsing nozzle has been added to Handler III models to ensure proper cleanout when switching chemicals.

Designed specifically to work with a Banjo 3″ polypropylene pump powered by a Honda GX200 engine, water bypass rates are accomplished with almost no reduction in flow your sprayer. Features include:

- Full 10L/20L container emptying and rinsing capabilities.

- Dual inlet venturi and bulk draw capabilities.

- Integrated transfer pump.

- Comes with the original Handler knife.

- Closed loop recirculation and agitation.

- Tank emptying by venturi or direct pump draw.

QUICK SPECIFICATIONS

- 70 US GAL/275L

- 3” CAMLOCK CONNECTIONS

- 16” HINGED AND LOCKABLE LID

- 2” DUAL INLET VENTURI

- 3” BANJO PUMP/GX200 HONDA ENGINE

- ROTOCRAFT TANK RINSING NOZZLE

H33HD

The H33HD has been designed specifically to work with new 3” pumps being made with flows in excess of 280 GPM (1060 LPM). At these flow rates, water in 3” plumbing moves in a fully turbulent motion and creates significant line pressures and risk of water hammer. Engine power requirements increase with these pumps and so does the need to match your chemical inductor properly.

With a re-designed bypass line free of directional changes, the H33HD takes full advantage of your pump’s flow potential. As a safety precaution against the higher operating pressures, the H33HD is also equipped with a pressure spike relief valve to prevent water hammer damage. Maximize the performance of your high volume 3” pump without sacrificing safety by using the purpose built H33HD. Your Handler dealer will be glad to help determine when the H33HD is the right Handler for you. Features include:

- Uni-directional bypass line for maximum flow.

- Pressure spike relief valve to prevent damage.

- Full 10L/20L container emptying and rinsing capabilities.

- Dual inlet venturi and bulk draw capabilities.

- Comes with the original Handler knife.

QUICK SPECIFICATIONS

- 70 US GAL/275L

- 3” CAMLOCK CONNECTIONS

- 16” HINGED AND LOCKABLE LID

- 2” DUAL INLET VENTURI

- ROTOCRAFT TANK RINSING NOZZLE

H33HDP13

The H33HDP13 utilizes Hypro’s 3” polypropylene pump and the proven Honda GX390 (13HP) engine complete with electric start. Sprayer fill time is minimized with Handler bypass flow rates of 350 GPM (1325 LPM) thanks to the Hypro pump and our HD purpose built plumbing. 3” flow rates this high create higher operating pressures and the H33HDP13 is designed to handle them. The pressure spike relief valve eliminates any risk of water hammer which ensures operator safety along with protecting your equipment.

Even though the plumbing arrangement is different from other H2 and H3 Handlers, the H33HDP13 maintains all of the functionality you’ve come to expect in a Handler, including sprayer filling container emptying and rinsing, venturi based bulk chemical induction, tank emptying with venturi or direct pump draw, closed loop circulation and agitation, and wash line. Features also include:

- Uni-directional bypass line for maximum flow.

- Pressure spike relief valve to prevent damage.

- Full 10L/20L container emptying and rinsing capabilities.

- Dual inlet venturi and bulk draw capabilities.

- Comes with the original Handler knife.

- 350 GPM (1325 LPM) bypass rates.

QUICK SPECIFICATIONS

- 70 US GAL/275L

- 3” CAMLOCK CONNECTIONS

- 16” HINGED AND LOCKABLE LID

- 2” DUAL INLET VENTURI

- ROTACRAFT TANK RINSING NOZZLE

- 3” HYPRO PUMP/GX390 HONDA

- ELECTRIC START (12V POWER NOT INCLUDED)

H43P65 and H43P65V

The Handler IV is the king of batch induction systems with its larger liquid volume and incredible agitation capability. The H43P65V comes complete with a total drainage tank, Banjo 3” pump, a dual inlet venturi for bulk chemical induction, twin agitation lines, two 16” hinged lids (one with the Handler Knife and one without), container and tank rinsing nozzles, a 4-way forkliftable steel frame, and a pump containment tray. Using closed loop recirculation through the exclusive dual inlet venturi, this model is able to induct bulk chemical into the Handler tank without your sprayer needing to be there! Whether it is high volumes of liquid pesticides or large amounts of dry flowables needing to be agitated, a Handler IV can do it all before your sprayer is back to be filled.

Dry AMS (ammonium sulfate) users may be interested in even more agitation. The similar model H43P65 replaces the venturi with a second 2” full port agitation line and provides agitation strong enough to dissolve even AMS that is not spray-grade. Features include:

- Twin agitation lines.

- Comes with The Handler knife.

- Closed loop recirculation and agitation.

- Full 10L/20L container emptying and rinsing capabilities.

- Dual inlet venturi for driving bulk chemical into the Handler or direct to sprayer fill line.

QUICK SPECIFICATIONS

- 230 US GAL/870L

- 3” CAMLOCK CONNECTIONS

- TWO X 16” HINGED AND LOCKABLE LID

- 2” DUAL INLET VENTURI

- ROTACRAFT TANK RINSING NOZZLE

- 3” BANJO /GX200 HONDA

H43P13V

Taking advantage of the new high-volume pumps available today, the H43P13V reduces sprayer fill time yet again. With bypass rates of 350 GPM made possible by the 3” Hypro polypropylene pump, this is the fastest Handler IV yet. In addition to the increased bypass speed, the pump provides higher pressures and creates even greater agitation than the H43P65V. Using closed loop recirculation through the exclusive dual inlet venturi, this model is able to induct bulk chemical into the Handler tank without your sprayer needing to be there! Whether it is high volumes of liquid pesticides or large amounts of dry flowables needing to be agitated, a Handler IV can do it all before your sprayer is back to be filled.

The Honda GX390 engine comes standard with an electric start. Instructions on proper cabling are included for connection to your own battery or 12V power source. Even if your power is down, Honda’s trademark easy-starting engines with built-in decompression can be started with the manual recoil. Features include:

- Dual inlet venturi for drawing bulk chemical into the Handler or direct to sprayer fill line.

- Full 10L/20L container emptying and rinsing capabilities.

- Comes with the original Handler knife.

- Twin agitation lines.

- Closed-loop recirculation and agitation.

- 350 GPM (1325 LPM) bypass rates.

QUICK SPECIFICATIONS

- 230 US GAL/870L

- 3” CAMLOCK CONNECTIONS

- TWO X 16” HINGED AND LOCKABLE LID

- 2” DUAL INLET VENTURI

- ROTACRAFT TANK RINSING NOZZLE

- 3” HYPRO /GX390 HONDA

FREQUENTLY ASKED QUESTIONS

How can I make sure I am choosing the right model?

Our sales team have the experience needed to help you choose the right model. Contact us today to discuss your needs and how The Handler can fit into your operation.

How accurate are The Handler tank calibrations?

The Handler tank is designed to be relatively tall for their volume and this makes graduations more accurate. The calibrations are there to serve as a rough guide during your mixing and should not be used for actual measurement. Polyethylene tanks inherently change shape slightly under different temperature and load conditions and so the graduations will vary slightly in their accuracy.

How long can I expect my Handler to last?

The tank is constructed with a UV stabilized polyethylene resin and should easily withstand constant sun exposure for eight to ten years. Shaded or inside storage when not in sue will extend the life of the tank substantially.

My Handler knife is getting old and needs sharpening, is that possible?

Our first recommendation here is to replace the knife with a new one. We are proud to help farmers who have “worn out” their knife through use. For information on new replacement knife kits, contact our sales team. While it is possible to re-sharpen, it is also somewhat dangerous and should be approached with caution and appropriate safety gear. The knife itself cannot be disassembled which makes accessing the blades difficult. The best results come from the use of a flexible wheel in a very fine grit or even white felt.

Which Handler is best suited for mixing dry flowables and solubles?

While any of the Handlers will agitate these products, the best models are Handler II, III, and IV. Handler II and Handler III have identical agitation abilities but the Handler III tank and its larger capacity will do higher volumes of dry product. For large dry users, we recommend moving up to the Handler IV that will do any amount of dry needed in one sprayer fill. The H43P65 has two full 2” agitation ports and will perform at a higher rate of agitation than the H43P65V.

How does the venturi work?

A venturi is one example of Bernoulli’s Principle which says that an increase in speed of flowing liquid causes a reduction in pressure. As water enters the cone inside a Handler venturi, it is forced to speed up and at its highest flowrate the resulting pressure drop is great enough to act like suction through the inlet ports. That is why the Handler venturi has an arrow to indicate flow direction – it will not function properly if installed backwards or water pumped through it in the opposite direction.

Does the venturi perform the same functions on all Handlers?

No. On a Handler I a single inlet venturi is used and it draws liquid from the Handler tank and puts into the flow going to your sprayer. On all Handler II and Handler III models, the venturi draws from your choice of Handler tank or bulk container and discharges both into the flow going to your sprayer. On a Handler IV the tank is too large to be emptied by the venturi in a reasonable time so the suction of the venturi is only to bulk containers. The Handler IV venturi discharges into its own tank and not out to the sprayer. This is done so that the venturi can be used without a sprayer needing to be there to take the water flow.