THE ENGINEERED DIFFERENCE IN TANKS.

Polywest specializes in Made-to-Order, industrial grade, engineered polyethylene tank options.

Snyder Industries, our primary supplier for custom polyethylene tank applications, boasts the industry’s most complete product offering of polyethylene tanks and accessories that can be configured to achieve specific chemical resistance and functionality performance objectives in both single and double wall containment systems:

- Products can be designed to meet ASTM standards, ranging in sizes up to 16,500 US gallons, and can come equipped with a variety of options, including seismic / wind restraints, heat maintenance systems, sight gauges, ladder assemblies, flex couplings, and much more.

- Snyder offers a diverse range of material options, including: HDLPE (high-density) and XLPE (crosslink) resins, along with special resins designed for specific applications: An opaque white resin (#880059) designed for sodium hypochlorite; and resin (#880046) specifically for sulfuric acid.

- Snyder tanks are designed, built and tested to ASTM D 1998-06 Standards. Insist your tanks meet all aspects of ASTM. Snyder also offers NSF/ANSI Standard 61 listed tanks as shown by their listing on www.nsf.org. Snyder’s HDLPE resin complies with FDA Regulation 177.1520.

- Snyder matches each specific chemical to the correct tank material to ensure compatibility. All materials are UV stabilized for long-term outdoor service. Tank styles available include vertical and horizontal tanks, cone bottom tanks, IBC tanks and their highly engineered Captor double wall containment tanks.

- Included in the high level of quality control that have made Snyder tanks legendary are Wall Thickness Tests, Hydrostatic Water Tests,Low Temperature Impact Tests and O – Xylene – Insoluble Fraction (Gel Tests).

MARKET & APPLICATIONS

Water and Waste Water Treatment:

Municipalities using chemicals including Sodium Hypochlorite (bleach), Ferric Chloride, Sodium Hydroxide, Hydrofuluosilicic Acid, and Alum. Applications include bulk storage, day tanks, batch tank systems, mix tanks, surge tanks, rinse tanks, reverse osmosis and potable water tanks.

Industrial Chemicals:

Large variety of chemicals used in a multitude of industries including automotive (used oil collection tanks), aviation, textiles, plastics/rubber, mining, marine, paper/pulp just to name a few.

De-icing Chemical Products:

Highway/Road Pre-wet and De-Icing Chemicals including Calcium Chloride, Magnesium Chloride, Potassium Acetate (airports) and more.

Biodiesel & Ethanol Plants:

B-100 Storage, vegetable oil storage, tanks for Sulfuric Acid, Caustic Soda, Potassium Hydroxide, Urea and others.

Petroleum and Allied Products:

Lubricants, Offshore Drilling Companies, Oil Refineries, Oil & Oil Waste including Frac Tanks and Storage containers.

CAPTOR DOUBLE WALL POLY TANKS

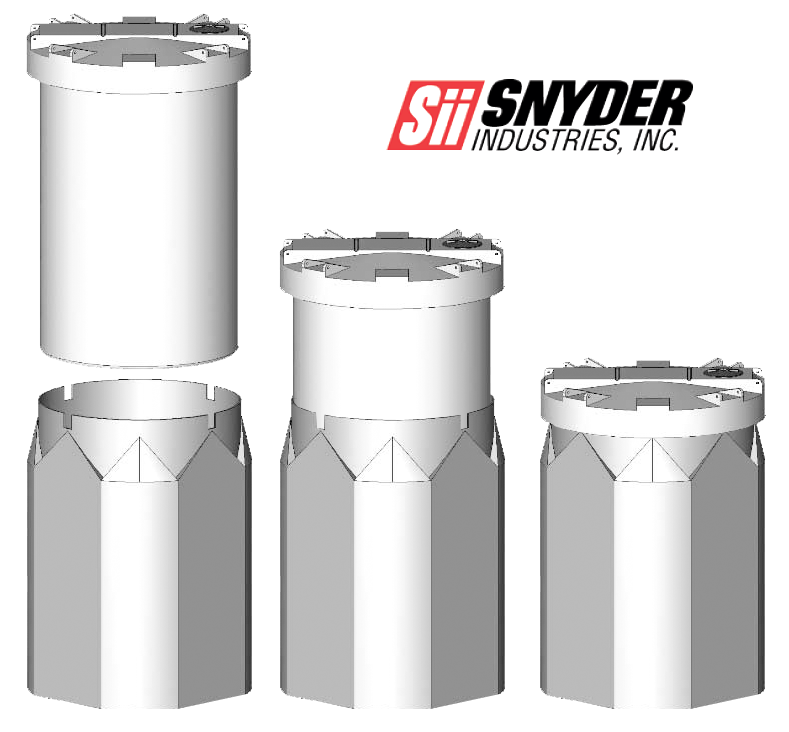

Snyder’s revolutionary Captor Containment System is designed to alleviate the ever-changing environmental and safety concerns regarding bulk chemical storage and containment for the 21st century.

Captor’s unique tank-in-a-tank design enables users and specifiers to incorporate advance performance and safety features on a bulk-handling system, which provides total containment protection. Captor’s double wall construction is completely enclosed so that external matter, such as dust, rain and snow is prevented from collecting in the outer containment tank.

Besides delivering unparalleled performance benefits, Captor Containment Systems also contribute to your company’s bottom line by significantly reducing installation and procurement cost. Every Captor is shipped fully-assembled on either a standard or wide load flat bed trailers, which reduces comparable costs by an average of 35 percent.

HOW DOES A CAPTOR GO TOGETHER?

| Part Number | Volume (Imp Gal) | Volume (US Gal) | Volume (litres) | Diameter (in) | Height (in) |

|---|---|---|---|---|---|

| 5040000N– | 460 | 550 | 2,080 | 76 | 65 |

| 5470000N– | 915 | 1,100 | 4,165 | 76 | 104 |

| 5490000N– | 1,290 | 1,550 | 5,865 | 76 | 136 |

| 5570000N– | 1,665 | 2,000 | 7,570 | 102 | 103 |

| 5580000N– | 2,085 | 2,500 | 9,465 | 102 | 122 |

| 5590000N– | 2,500 | 3,000 | 11,355 | 102 | 142 |

| 5600000N– | 2,915 | 3,500 | 13,250 | 102 | 158 |

| 5610000N– | 3,335 | 4,000 | 15,140 | 102 | 178 |

| 5620000N– | 3,750 | 4,500 | 17,035 | 102 | 197 |

| 5630000N– | 4,165 | 5,000 | 18,925 | 102 | 216 |

| 5660000N– | 4,585 | 5,500 | 20,820 | 120 | 172 |

| 5670000N– | 5,415 | 6,500 | 24,605 | 120 | 199 |

| 1006400N– | 7,250 | 8,700 | 32,935 | 142 | 197 |

| 1006600N– | 8,335 | 10,000 | 37,855 | 142 | 226 |

| 1031100N– | 10,415 | 12,500 | 47,500 | 142 | 274 |

| 1031300N– | 11,415 | 13,700 | 52,060 | 142 | 303 |

SNYDER ENGINEERED SINGLE WALL TANKS

Snyder is one of North America’s most complete fabricators of ASTM design and built polyethylene tanks.

- Vertical Tanks in sizes from 22 US gallons to 16,500 US gallons

- Horizontal Tanks in sizes from 30 US gallons to 3,400 US gallons

- Cone Bottom Tanks in sizes from 15 US gallons to 13,000 US gallons

- Open Top Tanks, PCO Tanks, Chemical Feed Tanks and Chemical Injection Tanks also available in varying sizes